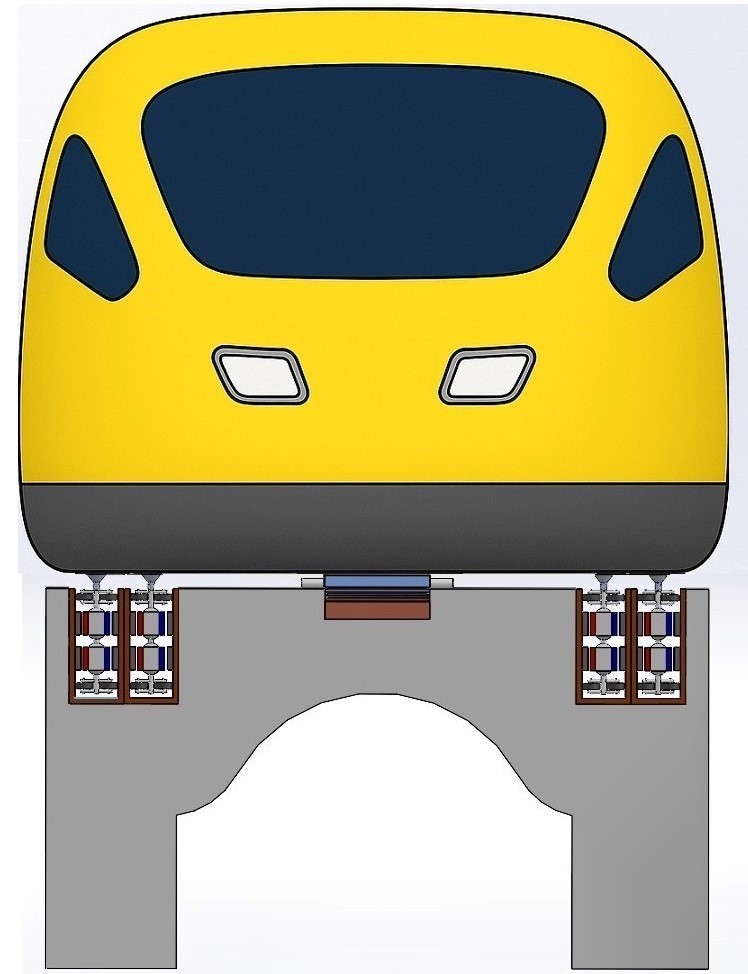

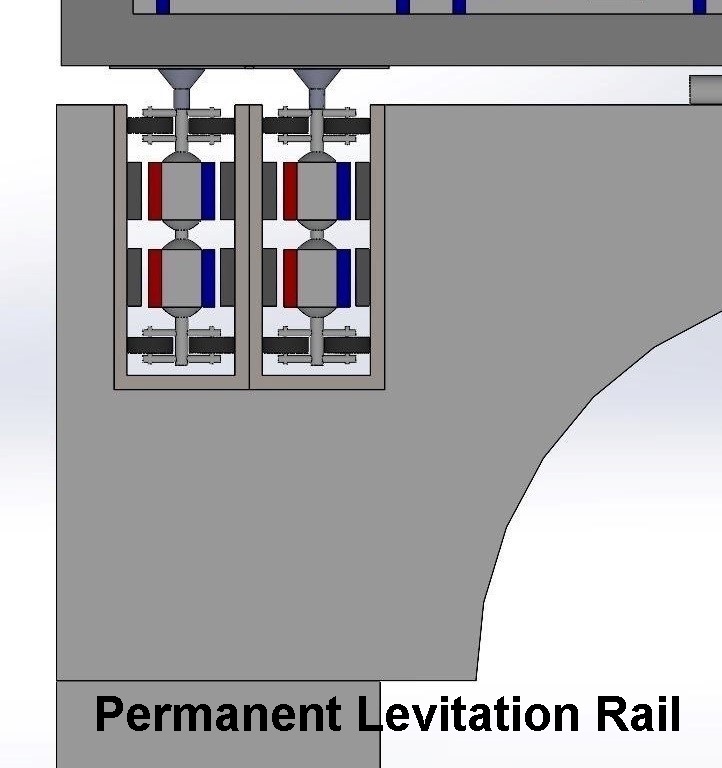

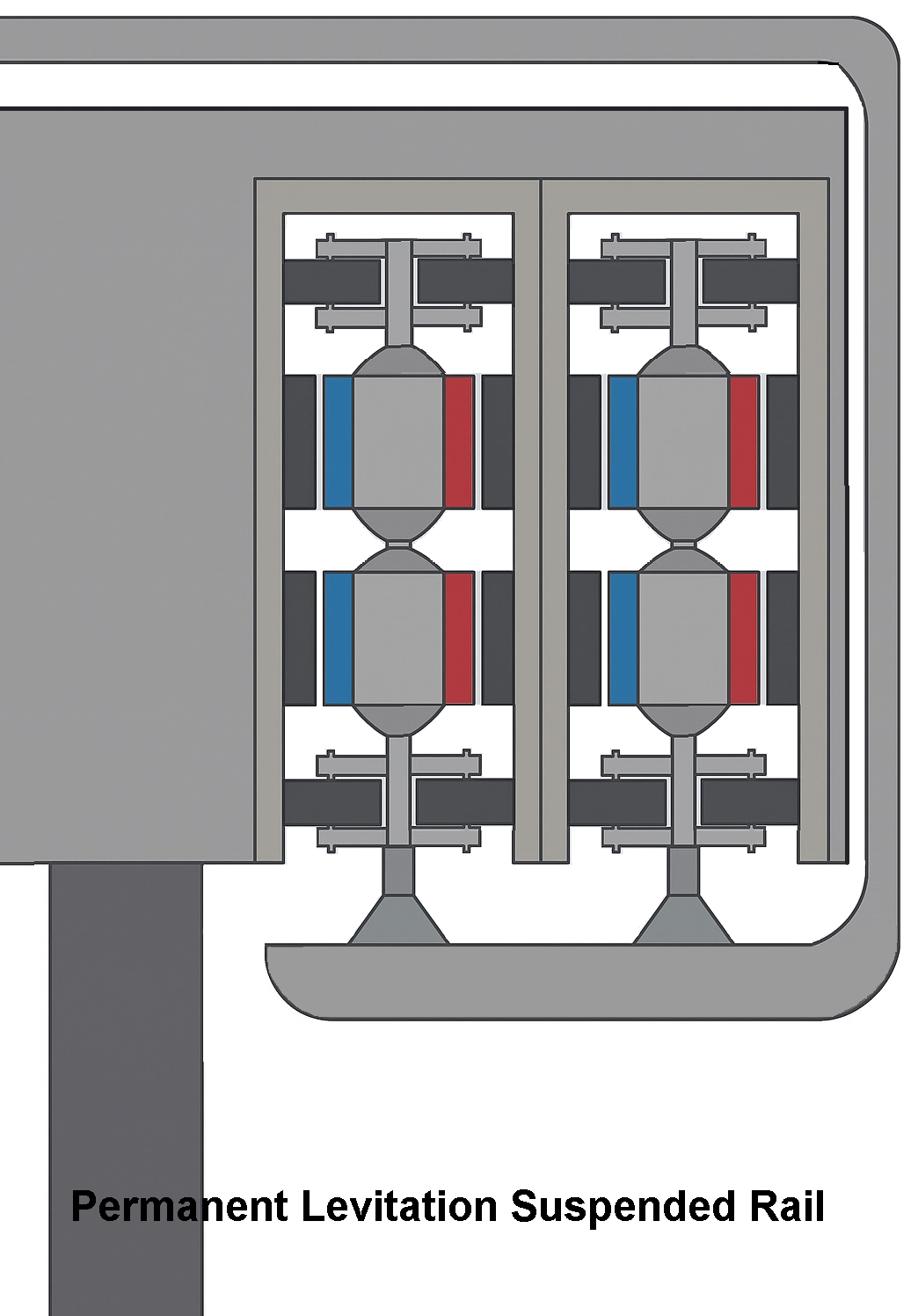

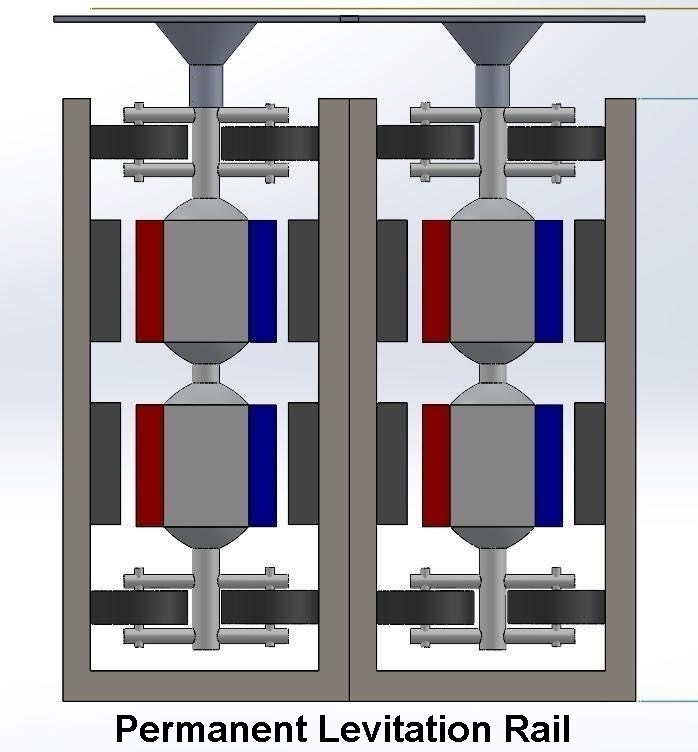

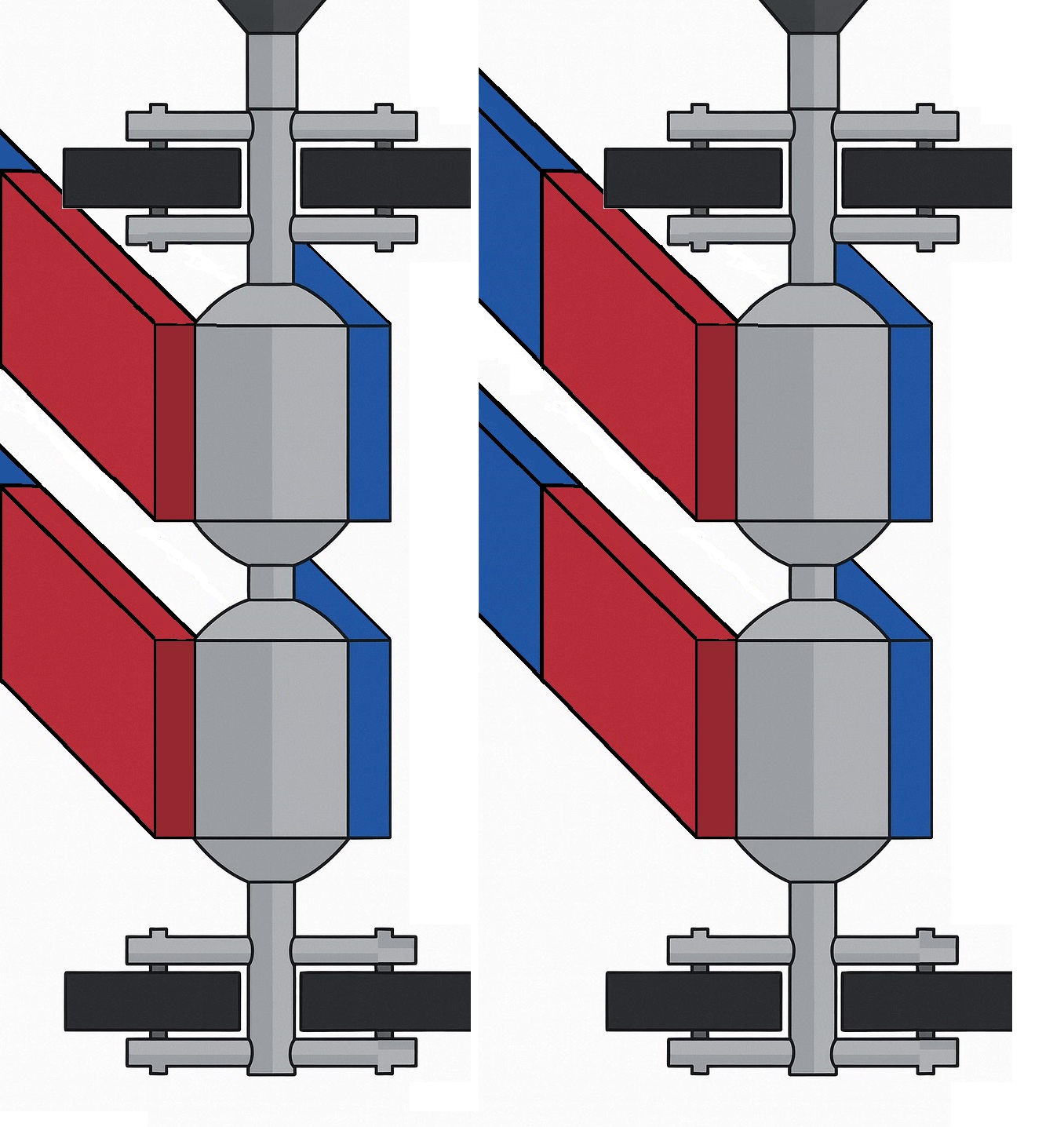

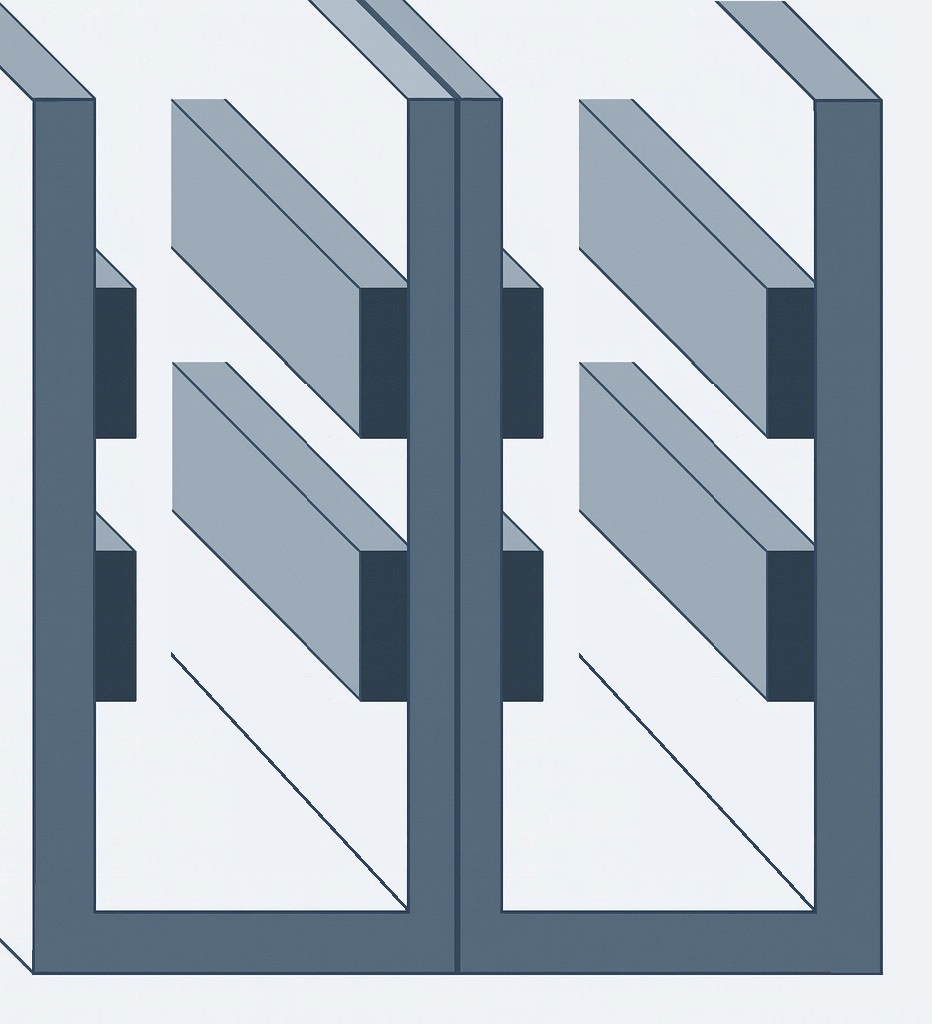

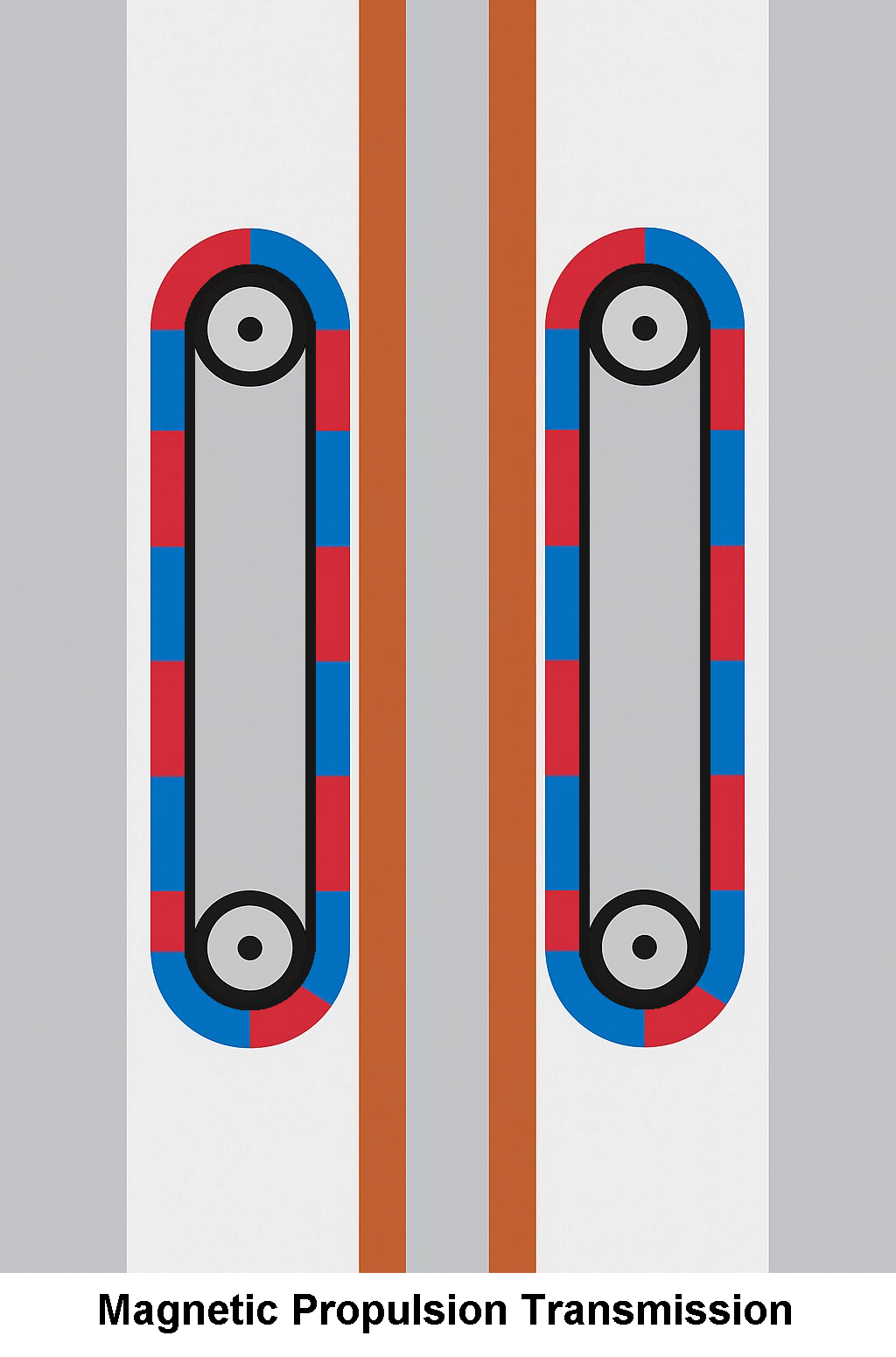

In that search, Parallel Energy and its technician developed a new and revolutionary technology for high- and low-speed trains. For this purpose, they developed a permanent levitation rail, using mainly iron in the form of flat bars along the entire length of the track and the use of permanent magnets in the shape of skids which, when installed on the train cars, allow this levitation system to support heavy loads.

The autonomy of each car produces energy savings. Its individual propulsion transmission is powered directly from the first car, allowing the addition of freight cars and platforms for vehicles, together with the passenger cars. The flexibility and safety of this technology, and its reduced cost, are unique.

.

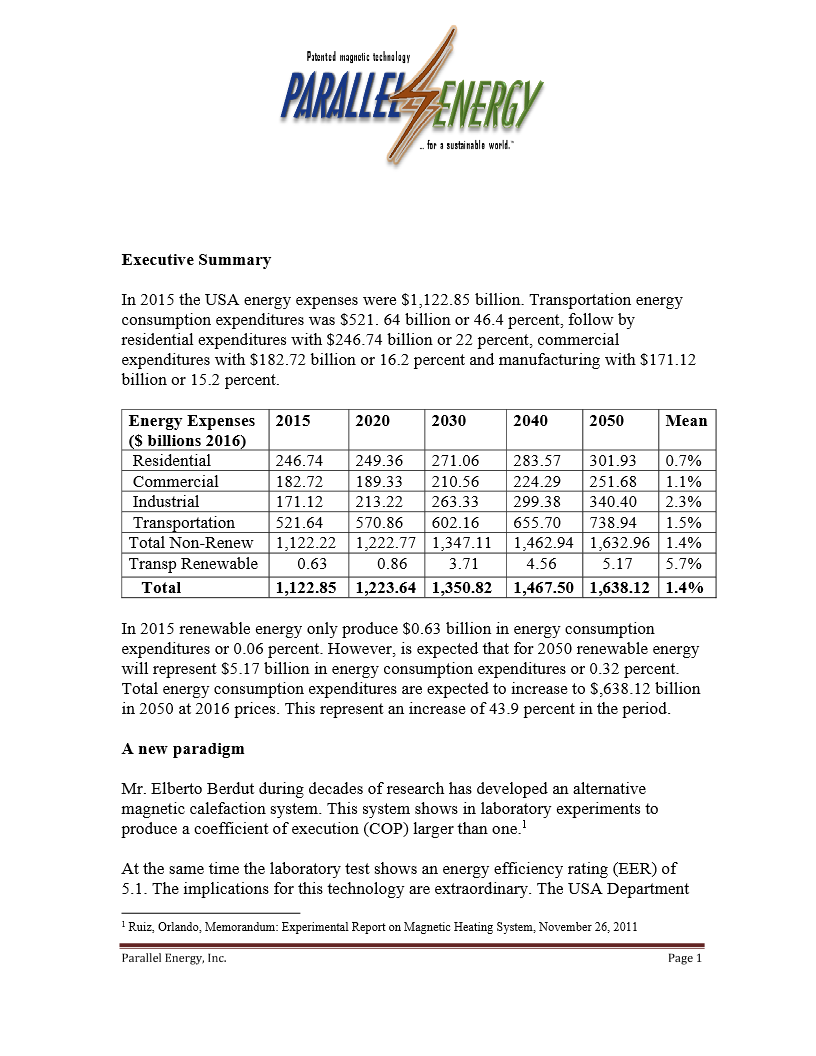

What is "Parallel Energy" for heating?

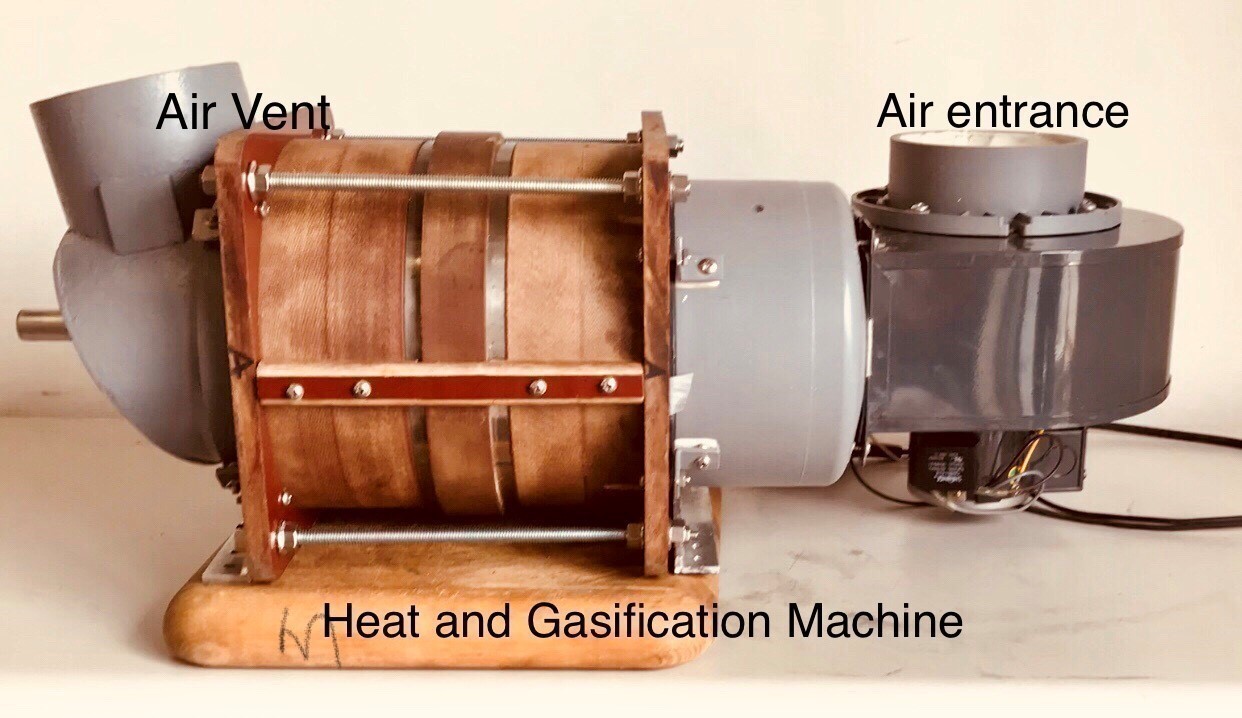

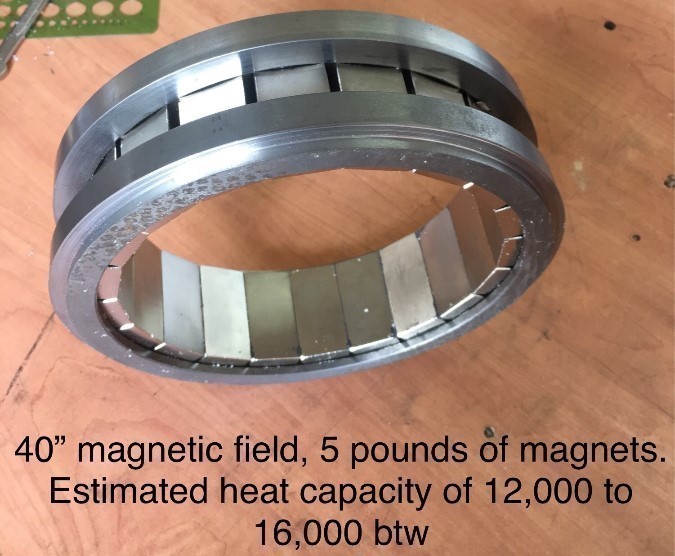

Our innovative “parallel energy” technology is based on the interaction between permanent rare-earth magnets and aluminum or copper. The interaction produces a chemical reaction that accelerates the electrons of the aluminum or copper, colliding with each other and creating heat. Temperatures reaching hundreds of degrees Celsius and efficiencies of 1 to 2 are achieved; in other words, for every 1,000 watts of energy consumed, this revolutionary technology produces 2,000 watts of heat. The energy savings is 50 to 60%.

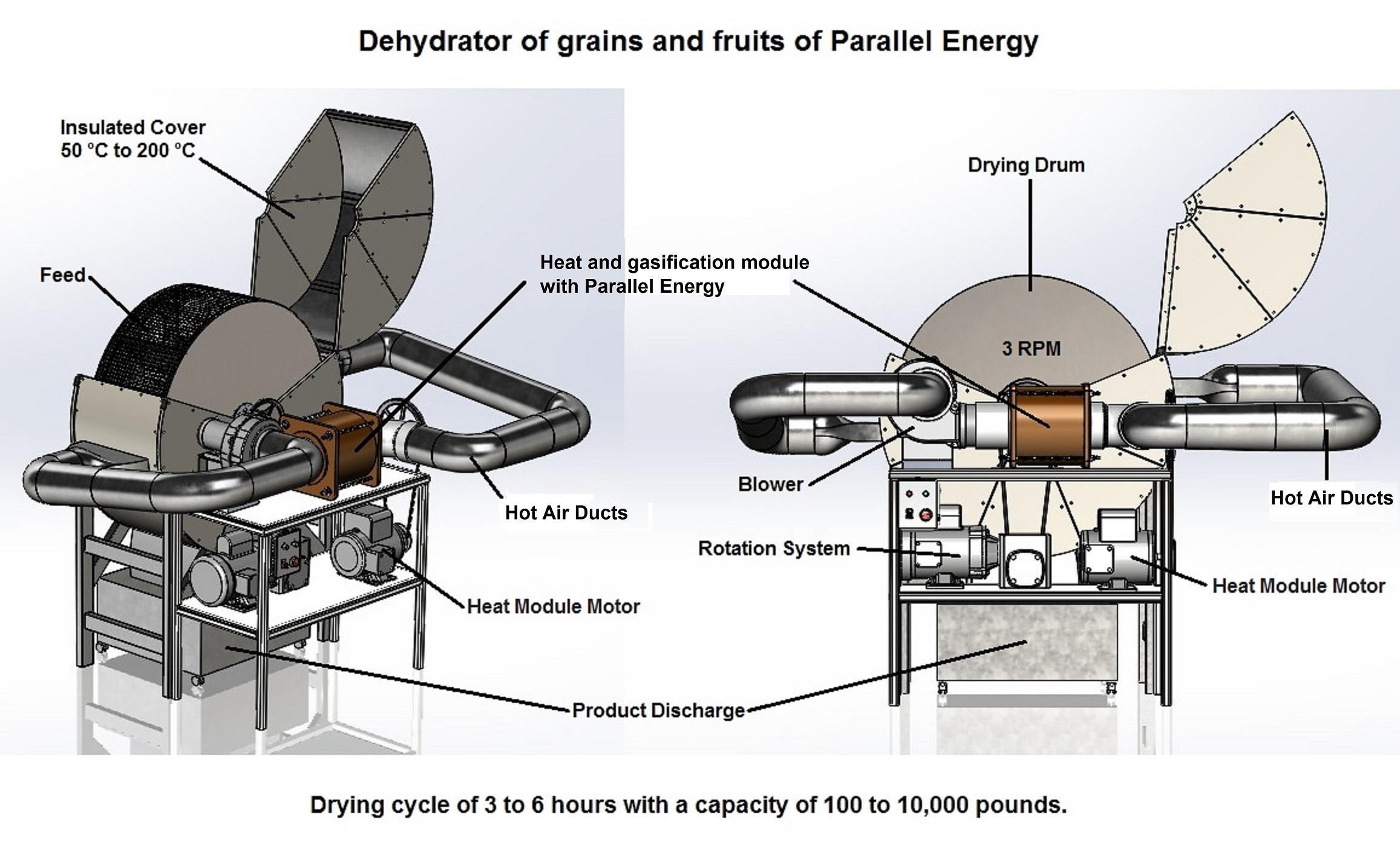

The applications are many: home heating, water heaters, dryers, drying coffee and cocoa beans, heat for electric vehicles, the industrial dehydration of food and innumerable other industrial uses among others. This technology will reduce the consumption of fossil fuels by hundreds of billions of dollars per year, improving the quality of the air we breathe, the economy of every socio-economic class... stabilizing oil prices and opening new pathways in science and technology for the sustainable development of our planet.

Our investigations continue… and everything indicates that it is possible our parallel energy technology can even gasify humid air, breaking apart water molecules and separating the water’s hydrogen from the oxygen, thereby producing the cleanest energy that can be produced and at a very low cost.

The monetization of an innovative new technology for clean, sustainable, energy.

The marketing of our revolutionary Parallel Energy technology will be effected through the sale of rights for the life of he patent, either via exclusive or partial rights, by countries or specific zones for each use or application. We will produce actual functioning prototypes or graphic simulations, always guaranteeing the efficiency and performance of each device to ensure the quality of the rights offered. We will have a laboratory with specialists and experts in the performance of this technology and will have individual patents for each device and its function. The sale of rights will primarily be made to industrial corporations related to the offered technology. Royalties and commissions will be required from the sale of each appliance as well as spare parts and a participation in any resale of rights to other interested parties. Parallel Energy Inc., is willing to partner with serious brands and entrepreneurs having the capacity to develop new appliances featuring the quality required by consumers. We are open to evaluating proposals, new ideas and will continue this revolutionary research in our laboratory and workshop for the benefit of consumers and our new associates.

Some Of Our Patents

After several years of research we have several patents submitted and ready for development.

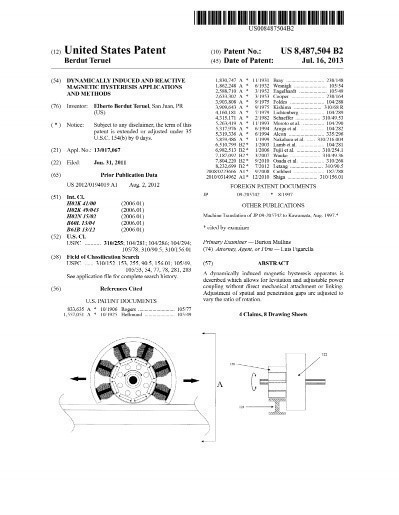

Dynamically induced and reactive magnetic hysteresis applications and methods

Dynamically induced and reactive magnetic hysteresis applications and methods